What Is Induction Heating?

Induction heating is a fascinating process in which metals or other conductive materials such as graphite are bonded, melted, softened or hardened by means of wireless heating technology. For many modern manufacturing processes, induction heating offers an attractive combination of speed, consistency and control. Induction heaters play a vital role in the smelting and automobile industry as well. Induction heating relies on the unique characteristics of radio frequency (RF) energy - that portion of the electromagnetic spectrum below infrared and microwave energy. Since heat is transferred to the product via electromagnetic waves, the part never comes into direct contact with any flame, the inductor itself does not get hot and there is no product contamination (see figure 1). When properly set up, the process becomes very repeatable and controllable

Figure 1 : A workpiece being heated by an induction heater

How Does An Induction Heater Work?

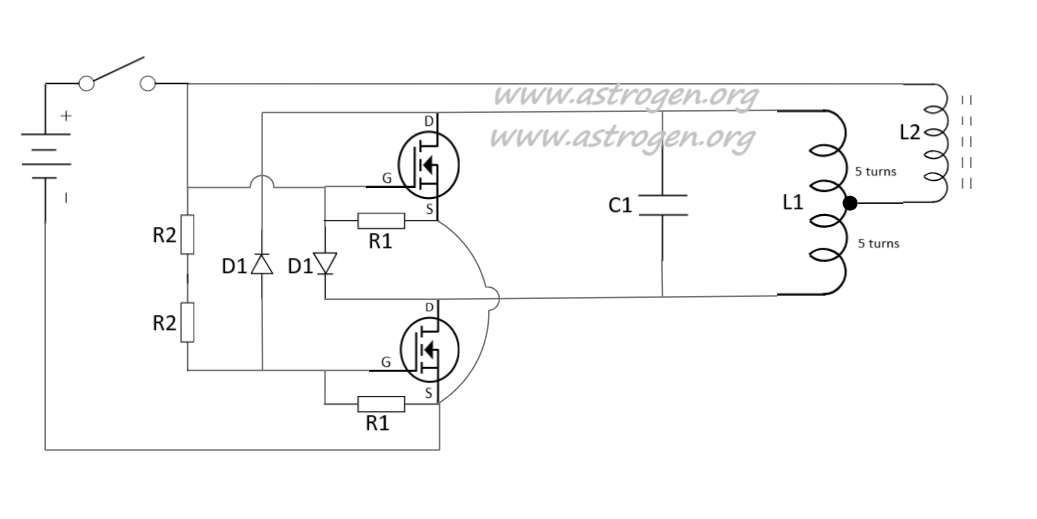

How exactly does induction heating work? It helps to have a basic understanding of the principles of electricity. When an alternating electrical current is applied to the primary of a transformer, an alternating magnetic field is created. According to Faraday’s Law of Induction, if the secondary of the transformer is located within the magnetic field, an electric current will be induced. In a basic induction heating setup, a power supply supplies 12Vdc input voltage through an oscillator circuit (shown in figure 2) that drives a transformer with high frequency, high amperage electric current. Here, the inductor (often a copper coil) serves as the transformer primary and the part to be heated becomes a short circuit secondary. When a metal part is placed within the inductor and enters the magnetic field, circulating eddy currents are induced within the part.

Figure 2: A basic circuit that can be used to make an induction heater.

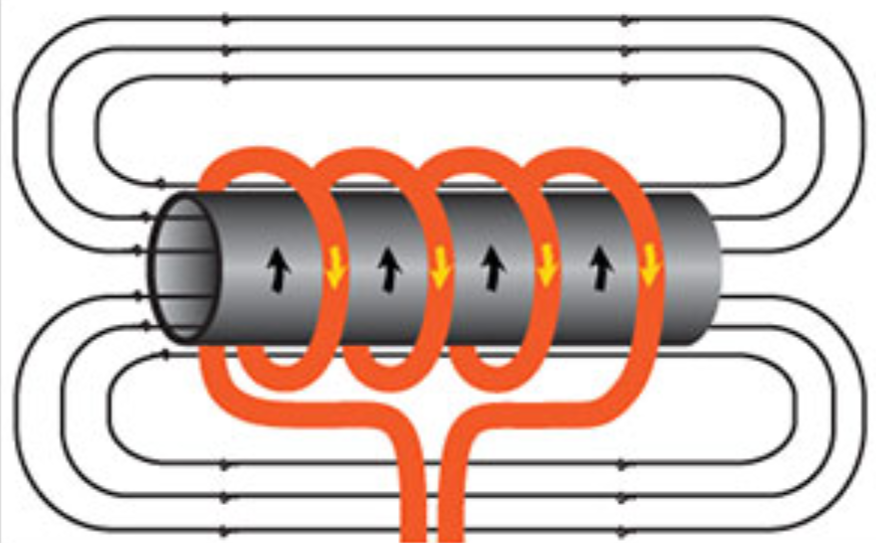

As shown in Figure 3, these eddy currents flow against the electrical resistivity of the metal, generating precise and localized heat without any direct contact between the part and the inductor. This heating occurs with both magnetic and non-magnetic parts and is often referred to as the Joule effect, referring to Joule's first law – a scientific formula expressing the relationship between heat produced by electrical current passed through a conductor.

Figure 3: The eddy currents flow against the electrical resistivity of metals

Secondarily, additional heat is produced within magnetic parts through hysteresis – internal friction that is created when magnetic parts pass through the inductor. Magnetic materials naturally offer electrical resistance to the rapidly changing magnetic fields within the inductor. This resistance produces internal friction which in turn produces thermal energy.

In the process of heating the material, there is therefore no contact between the inductor and the part, and neither are there any combustion gases. The material to be heated can be located in a setting isolated from the power supply; submerged in a liquid, covered by isolated substances, in gaseous atmospheres or even in a vacuum.

Terms to understand

1) Faraday's Law of Induction: Whenever a conductor is placed in a varying magnetic field, an electromotive force is induced.

2) Joule Effect: The process where the energy of an electric current is converted into heat as it flows through a resistance.

Why Do We Use Induction Heating?Induction heating has played essential roles over the years in industries relating to food (for making cans), cable, shipbuilding, aerospace, jewelries and many other factories that deals with shaping, joining and cutting the metals. Nowadays, traditional stoves are rapidly being replaced by electric stoves within which there lies an induction heater! Just like this, usage of this type of heating system is hugely increasing all around the world since the early 20th century. But what are the advantages which make this technology such crucial in so many different types of industry? Here’s the answer:

- Improved process efficiency of up to 90%.

- Localized, constant and precise heating.

- Temperature can be controlled very easily.

- Fast and energy saving technology.

- Uses electricity for heating instead of oxygen or fossil fuel.

- No combustion byproducts and pollutant gas released thus ensuring a cleaner workplace and environment.

- No open flames or fumes thus causing it to be a very safe heating process.

How To Make One At Home?

Here comes the most interesting part and surely the part for which you are here. How to make a very basic working model of an induction heater at home? Follow the steps:

1. Make sure you have all the components that are listed below:

- Two 10Kohm resistors ¼ watt (R1)

- Two 470ohm resistors ¼ watt (R2)

- Two UF 4007 diodes (D1)

- Two IRFZ44N MOSFETs with heat sink

- One 225J 400V capacitor (C1)

- 18AWG copper wire

- 40uH to 200uH inductor (L2) or make it by yourself by taking a ferrite core and giving 20 to 25 turns of the 18AWG copper wire around it.

- Soldering Iron and Soldering Wire

- 12V 5A DC power supply

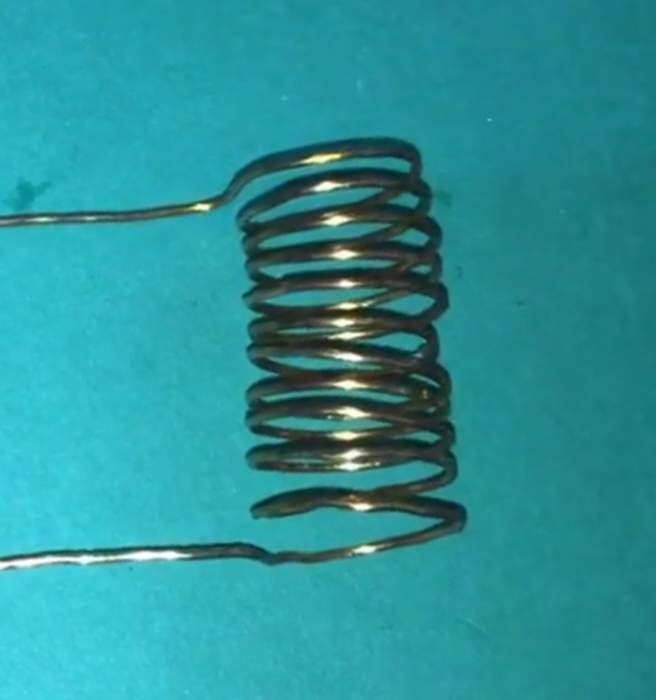

2. Take the 18AWG copper wire and a thick marker (or anything similar in size which has a cylindrical shape). Turn the wire around the marker 11 times to get your air inductor (L1). Now, on the 6th turn connect the L2. Now set up rest of the circuit as shown in the circuit diagram given in figure 2.

Figure 4: Turns of the working coil (air inductor)

3. Now you have your own induction heater! But wait. Before unveiling your project to the world, isn't it time for a test? Yes! Take out a long thin conducting material like screw, metal rod, etc. and hold it inside the working coil (as shown in Figure 1). Enjoy the wonderful sight of that specific area of the metal, which inside the coil, glowing red!

That's it! You're done! To know more about the applications of induction heaters, stay tuned with us because soon we are going to come back with another blog on one of the most extraordinary applications of such induction mechanisms in the industry.